Direct wiring a fuel pump is a relatively simple job that can be completed in a few steps. The process involves running a power source directly to the fuel pump, bypassing the vehicle’s existing electrical system.

Parts Needed

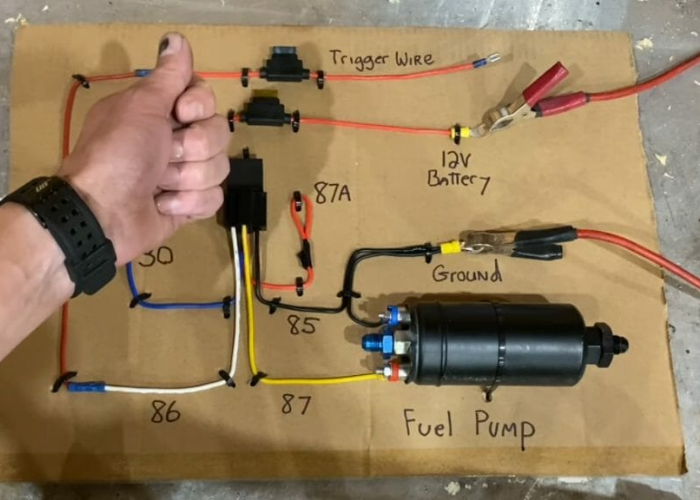

When it comes to direct wiring a fuel pump, the parts needed are relatively simple. First and foremost, you will need a fuel pump wiring kit. This kit will include the wiring harness, a relay, and the required fuses and terminals. You will also need a 12-volt power source, such as a battery or an alternator, and a fuse box. Finally, you will need a wire stripper, wire cutters, and an appropriate-sized wrench. With these items in hand, you are ready to wire up the fuel pump.

Preparing the Install Location

Preparing the Install Location for Direct Wiring a Fuel Pump is the first step in the process. This stage should be completed with extreme care and attention to detail. First, locate a suitable place for the fuel pump to be mounted. Make sure the location is not too close to any heat sources, such as an engine or exhaust. The ideal mounting location should be away from any moving parts and in a dry and clean environment.

Once the location is chosen, remove any dirt or debris from the area with a vacuum or a soft cloth. Then, use an adhesive to secure the fuel pump in place. Finally, check to make sure the pump is level and secure. If it is not level, use shims or spacers to level it. This will ensure the fuel pump receives an even flow of fuel and provides a better performance.

Safety Considerations

When direct wiring a fuel pump, safety should always be the number one priority. Before beginning the project, the fuel pump must be disconnected from the vehicle’s electrical system. This can be done by locating the fuel pump fuse and removing it from the fuse box.

Additionally, the battery must be disconnected and grounded to prevent any potential sparks from occurring. It is also important to wear protective gear such as safety glasses and gloves during the wiring process. Once the fuel pump is disconnected from the vehicle, it is important to take the necessary safety precautions to ensure that the wiring is done correctly. This includes ensuring the correct wire size and type is used, and that the wires are connected to the proper terminals.

Additionally, it is important to double check all wiring connections to ensure that they are correctly wired and secured. Finally, it is important to use the proper electrical tape and heat shrink tubing to cover all exposed wires and prevent any sparks or other electrical issues from occurring. Taking these safety precautions can help ensure a proper and safe direct wiring of the fuel pump.

Preparing the Fuel Pump

Preparing the Fuel Pump is an important step in the direct wiring process. Before beginning the wiring, you will need to make sure the fuel pump is properly installed and secured. If the fuel pump is not correctly installed, it may cause a dangerous situation as the wiring may be exposed to the elements.

Begin by ensuring the fuel pump is securely mounted onto the vehicle using the appropriate mounting hardware and brackets. You should also make sure that the fuel pump is positioned away from any hot components such as the engine or exhaust system. Once the fuel pump is securely installed, you will be ready to begin the wiring process.

Connecting and Labeling the Wires

Connecting and Labeling the Wires is the most important step when it comes to direct wiring a fuel pump. The first step in this process is to locate the fuel pump’s power source. This is typically a 12-volt battery source. Once the power source is located, the next step is to connect the positive and negative wires from the fuel pump to the power source.

This should be done by using a soldering iron and heat shrink connectors to ensure a secure connection. Once the positive and negative wires are connected, it’s important to properly label each wire. This can be done using electrical tape or heat shrink labels for easy identification. It’s important to note that the negative wire should be connected to the black ground cable on the power source. After the wires are properly labeled, it’s time to secure the wires in place. This can be done by using zip ties or wire looms to ensure the wires are kept safe and secure. Once the wires are connected and labeled, the fuel pump is ready to be tested.

Securing the Wires

Securing the Wires: Once the wiring has been run from the battery to the fuel pump, it is important to ensure that the wiring is properly secured and cannot come loose. This can be accomplished by using zip ties or other types of wire ties to secure the wiring to the fuel pump or any other part of the vehicle.

Make sure that the wiring is secured firmly and that there is no slack in the wiring. Additionally, if the wiring is exposed, it should be wrapped with electrical tape to ensure that it is protected from any moisture or dirt that may come into contact with it. This will help to protect the wiring from any damage that could be caused by the environment.

Testing the Connection

Before testing the connection, it is important to ensure the fuel pump is wired correctly. To do this, check the wiring diagram and make sure the wires are connected to the fuel pump correctly and securely. Next, you will need to disconnect the negative battery cable from the vehicle. This is done to ensure you do not get an electrical shock when you test the connection.

Once disconnected, it is time to test the connection. To do this, you will need a multimeter. Connect the multimeter’s positive lead to the fuel pump positive lead and the multimeter’s negative lead to the fuel pump ground lead. Make sure to select the correct voltage setting on the multimeter to match the voltage of the fuel pump. Then, turn the multimeter on and check the voltage reading. If the readings are correct, the connection between the fuel pump and the power source is good. If the readings are not correct, you need to check the wiring and connections again.

Conclusion

Direct wiring a fuel pump is a complicated but rewarding task. It requires a lot of patience and a working knowledge of electrical systems and fuel pumps. After successfully wiring the pump, the vehicle should start and run like normal. It is important to remember to follow all safety precautions when dealing with electricity and to double-check all connections to make sure they are secure. Taking the time to properly wire your fuel pump will save you money in the long run, and will ensure your vehicle is running safely and efficiently.